Scanflow represents a cutting-edge AI scanner designed for smart devices, aiming to revolutionize data capture and workflow automation across various industries, particularly in manufacturing and automotive sectors. This innovative tool leverages AI-driven technology to ensure industry-grade quality control, significantly enhancing the efficiency and accuracy of production processes.

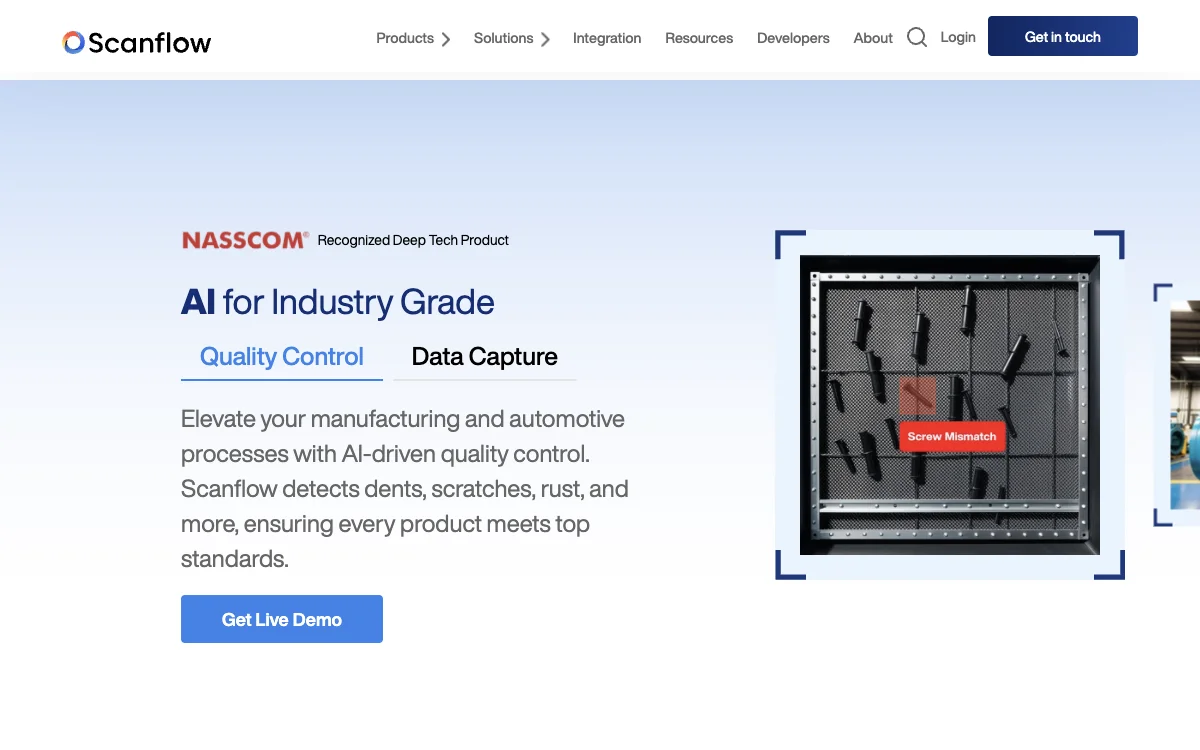

At its core, Scanflow specializes in detecting a wide range of imperfections such as dents, scratches, rust, and foreign objects on products. This capability ensures that only products meeting the highest standards reach the market, thereby reducing costly returns and enhancing customer satisfaction. Moreover, Scanflow's AI-powered barcode scanning solution streamlines inventory management and supply chain processes, offering precise and rapid data capture.

One of the standout features of Scanflow is its ability to extract essential vehicle details from VIN numbers, including make, model, year, and specifications. This feature facilitates efficient vehicle management and inspection processes, making it an invaluable tool for the automotive industry. Additionally, Scanflow's serial code scanning technology ensures product authenticity and prevents counterfeit goods, further safeguarding brand integrity.

Scanflow also offers a comprehensive end-to-end quality control solution, encompassing customized hardware identification, flexible deployment options, output delivery systems, and continuous improvement processes. This holistic approach not only enhances product quality but also significantly reduces turnaround times and increases workforce engagement.

Industries such as automobile manufacturing, electronics, and pharmaceuticals can greatly benefit from Scanflow's solutions. By automating data capture and workflows, businesses can achieve increased compliance with industrial safety regulations, reduced errors, and enhanced productivity and ROI.

In conclusion, Scanflow is a versatile and powerful AI tool that addresses critical challenges in quality control and data management. Its ability to integrate seamlessly with existing systems and provide real-time insights makes it an essential asset for any business looking to elevate its manufacturing and automotive processes.